Smart Harvest

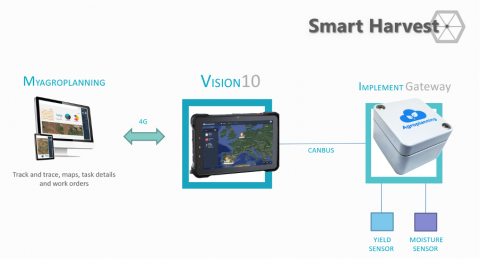

Smart Harvest is a system being created in the context of the Poshmyco research project (ICTAGRI-FOOD) with the aim to collect and transfer real time information between a combine and the office. The system consists of a display (installed in the cab) and the necessary sensors to collect GNSS (positioning and speed information) and actual crop data like yield and moisture. The system connects to a Cloud Application able to receive, store, display and edit all the data types. The software (FMIS) allows the fleet manager to create and send fields boundaries, work orders or prescription maps from the office to the machine and to receive actual positioning and information from the field. The user interface in the cab has been designed to display Selective Harvest maps, a new concept within Precision Agriculture, developed by the Poshmyco consortium. The SH are zone maps that shows spatial differences between High and Low quality grain, mainly calculated or estimated from previous field analysis. Estimated content of Mycotoxins will be used as main indication of grain quality. These maps are loaded into the Web Application and shared remotely with the display in the combine. During the harvest, the operator is assisted from the display in order to perform the selective harvest, taking into account some subjects like the machine and field dimensions. When the harvest is done, all data collected by the Smart Harvest System will be transfer to the office for further analysis and backup.

The innovation is a bundle of hardware and software consisting in the following parts: - A specific application has been developed for a 4G Android 9.0 robust tablet. - The application has an embedded Geographical Interface System able to display satellite images and custom maps (raster’s and vectorial). - RS232 communication to an external GNSS receiver and positioning of the machine current location in the map. - CAN communication to the machine and sensors to receive, show and attach to the current location all relevant information. - User authentication and machine identification. - Field boundaries and work orders synchronization with the cloud Web Application. - Shows the status and position from other machines in the same fleet. - Display of SH zone maps and calculation of the optimal harvesting route based on machine and field settings. - Real time calculation and display of yield and humidity maps.

Mycotoxins have a significant impact on food safety. Overall, foods contaminated with aflatoxins present a clear food security threat regarding their impact on human health, especially concerning the established causal association with liver cancer, synergistic effects with hepatitis B, and potential association with growth inhibition and immune system suppression. Securing clean of mycotoxin contaminated grains will reduce the risk to human health, leading to improved food safety. Smart Harvest system will, for the first time, allow the possibility of representing ‘digitally’, ‘in situ’, the spatial distribution of mycotoxins in the crop and support the driver during the harvesting operation. The product can be harvested into different bucks depending of it’s quality and there for distributed for different purposes. The system will also collect all relevant information and use it as feedback to complete the farming cycle. As well, this information could be used to improve the overall traceability from the fields to the industry.

The innovation is a bundle of hardware and software consisting in the following parts: - A specific application has been developed for a 4G Android 9.0 robust tablet. - The application has an embedded Geographical Interface System able to display satellite images and custom maps (raster’s and vectorial). - RS232 communication to an external GNSS receiver and positioning of the machine current location in the map. - CAN communication to the machine and sensors to receive, show and attach to the current location all relevant information. - User authentication and machine identification. - Field boundaries and work orders synchronization with the cloud Web Application. - Shows the status and position from other machines in the same fleet. - Display of SH zone maps and calculation of the optimal harvesting route based on machine and field settings. - Real time calculation and display of yield and humidity maps.

We are currently on a testing phase of an functional, but limited, prototype, which has been designed and built during the 21/22 season. First field tests have taken place in the current cereal harvesting season, May 2022 in the south of Spain. Readiness of the hardware, in terms of robustness, reliability and precision have been proved, so as the main concerns regarding telecommunications between the servers and the field devices. Part of the user interface it is still under development, as it is linked to other research activities within the project consortium.